Construction dictionary

Construction terms explained briefly and factually

In our construction lexicon you will find construction terms and building knowledge, which provides information in alphabetical order on important terms, basics and matters in the field of construction technology, of course without claiming to be exhaustive.

Scaffolding systems

Scaffolding systems are temporary structures to provide a safe workplace on construction sites and the necessary access. They are used for the construction, maintenance, repair and demolition of structures. According to the regulation in Germany, scaffolding systems must also fulfill a protective function.

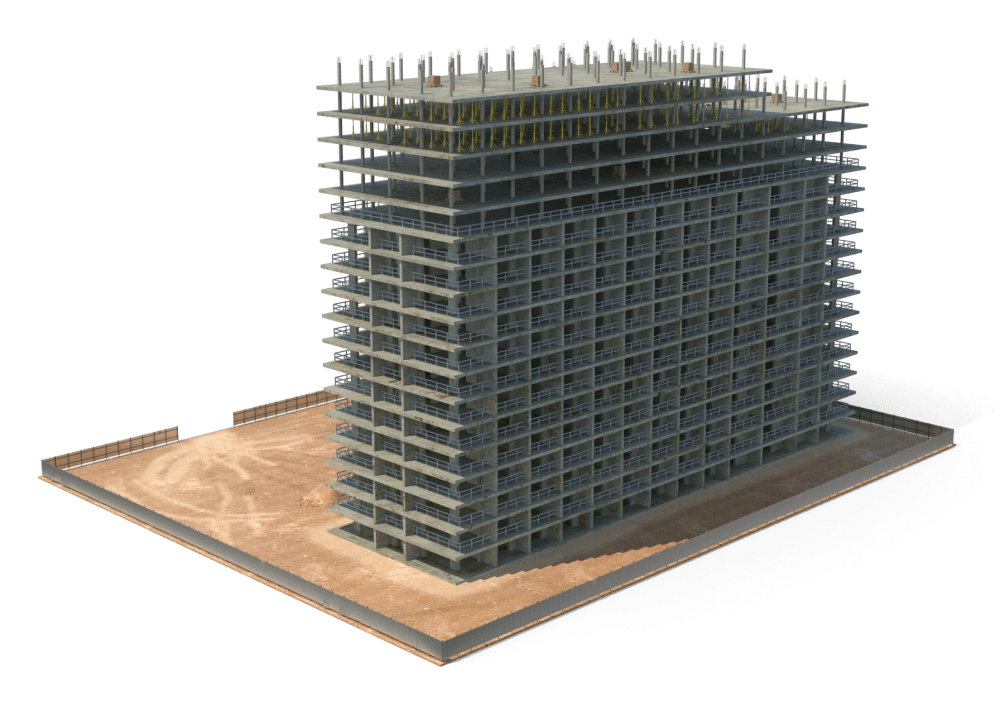

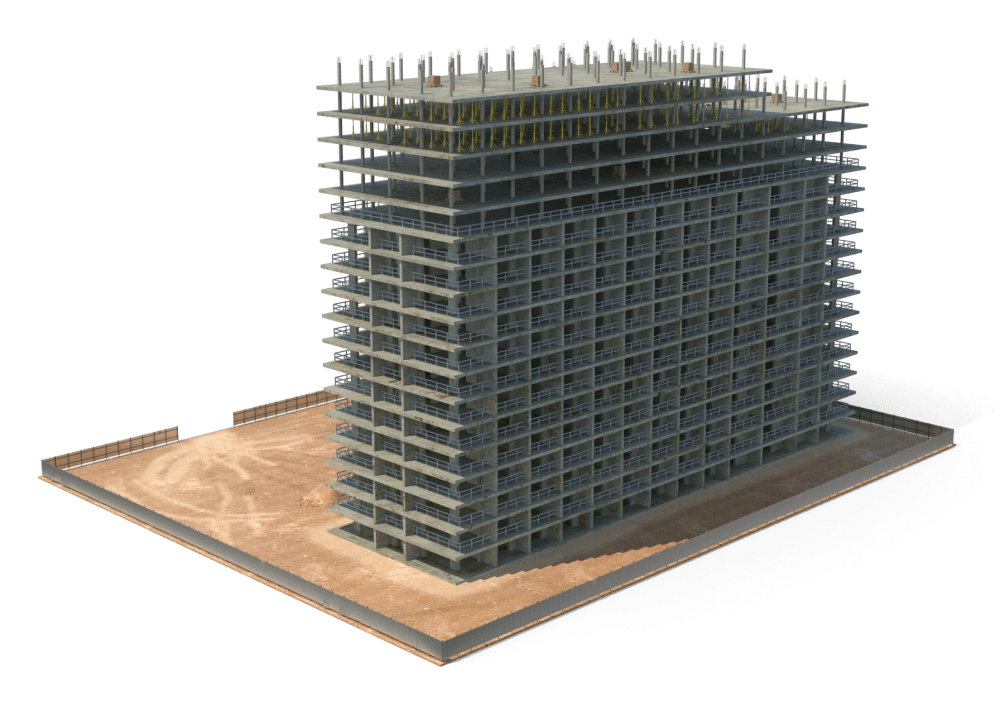

Construction site

A construction site (also called a work site) is a temporary production site specifically specified by the client, on which a structure is built, converted or demolished with the help of workers, machines, equipment and building materials, or on which a building project is carried out. A distinction is made between fixed construction sites and mobile construction sites, as well as between permanent construction sites and temporary construction sites according to the duration.

In addition to the names of building areas, there is so-called Construction field. This includes areas on the building site or in its immediate vicinity, on which building materials are stored, equipment is set up or the construction site facilities are housed during the construction period. In addition, there are areas and measures for traffic safety or construction site bypassing and bypassing in the vicinity of the construction site.

Slab formwork

Ceilings are switched off at the edges in various designs. The type of edge formwork depends on the structure. Different systems are available for slab edge shuttering and beams, depending on the requirements. Beam formwork enables the ceiling and the beam to be concreted in one operation without additional anchors and costly wooden supports, which significantly reduces the workload.

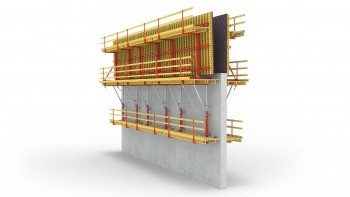

Edge formwork for walls

In areas with walls, the slab formwork closes on the inside of the walls. Therefore it cannot be used for the edge formwork. In this case, the vertical edge formwork is attached to the outside of the walls. There are different system solutions for this type of formwork, whereby the tie points of the wall formwork are used. The distance between the anchors results from the wall formwork system used (e.g. large-area formwork or panel formwork).

Edge formwork with exposed slab end

With free ceiling ends, the ceiling formwork can be combined with the edge formwork. In the case of edge supports, the formwork is bridged horizontally on site.

Ceiling formwork system

Slab tables are formwork systems with slab props, mostly in standard formats of 10 to 15 m², by means of which large slab areas can be realized in a few repositioning processes. To assemble the ceiling props, the table top structures are lifted with the crane. The slab tables are moved to the next operational position by crane or a moving car, additionally required slab tables are connected and the mating areas are connected with the conventional large-area formwork.

Compared to girder and panel formwork, which is switched on and off in individual parts, the workload is reduced considerably with slab tables. A mandatory requirement for the use of slab tables is, however, that the structure has a minimum formwork area. It is therefore necessary to determine beforehand whether the structure will cross this boundary and whether sufficient lifting platforms, cranes etc. are available for this type of ceiling formwork.

Scaffolding

Scaffolding is temporary construction of various uses and variable heights, lengths and widths. They are assembled on the construction site from individual scaffolding components to form shoring, protective scaffolding, work platforms or site accesses and disassembled again after their use. Modern system scaffolding that is used in scaffolding consists of prefabricated metallic components. Due to the high technical and safety requirements, the manufacture of scaffolding and its safe assembling and disassembling are subject to strict legal regulations.

Scaffolding differ according to the type of use, the type of construction and the type of training:

Usage type

- Scaffolding system (reinforced scaffolding, special scaffolding structures)

- Shoring systems

- Protective scaffolding (working scaffolding with clothing, protective roof, roof safety scaffolding, safety scaffolding)

Design type

- Type of execution (tubular steel coupling, frame scaffolding, ladder scaffolding, modular system)

- Support system (standing scaffolding, hanging scaffolding, bracket scaffolding)

Type of assembly

- Facade scaffolding

- Allround scaffolding

- Mobile scaffolding

Climbing formwork

Climbing formwork systems consist of wall formwork systems (girder or frame formwork) and different climbing brackets that are firmly assembled to form a moving unit. The advantage of the climbing formwork is that it can be set directly into the next concreting section to save time.

Depending on whether or not a crane is required to move upwards, a distinction is made between crane-dependent and crane-independent climbing / moving formwork. The crane-independent climbing formwork is called self-climbing formwork. This is moved to the next concreting section by lifting devices on climbing rails.

In the case of crane-dependent climbing formwork, a distinction is made between guided and unguided climbing / moving formwork. With guided climbing formwork, the scaffolding on which the formwork is attached is pulled up on guide rails with the crane. This enables safe implementation even in windy conditions. In the case of unguided climbing formwork, this is separated from the structure and hung in the next concreting section using a crane.

Panel slab formwork with drop head

Panel slab formwork with drop head enables the elements and the side members to be stripped early, which reduces the amount required. Drop head systems consist of supports, drop heads, cover strips and panels. The heads are secured to the supports with quick-release fasteners. A mechanism on the drop head can be used to lower the carrier and frame elements. In this way, the material can be used for the next job after just one day.

Panel slab formwork without early stripping

The formwork system of the panel slab formwork without early stripping consists of a column, column head and formwork element. The support heads are attached to the support ceiling with screws. Then the formwork elements are hooked into the column head, swiveled up and supported at the respective crossing point. In the case of heights of up to 3.20 m, which are common in residential construction, shuttering is done from the ground. At greater heights, mobile scaffolds or lifting platforms are used.

Frame scaffolding

Frame scaffolding (also known as plug-in frame scaffolding) consists of only a few individual elements that are quickly and easily assembled on site and dismantled again after use. The components of this steel scaffolding system are the base spindle, assembly frame, scaffolding deck, toe board, railing and diagonal. Screws are not required. They are mainly used for facades as work scaffolding, protective scaffolding or standing scaffolding.

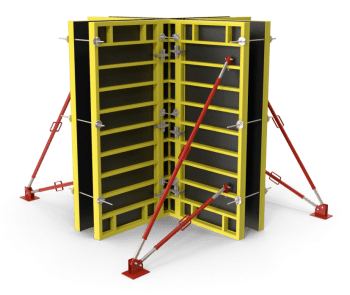

Frame formwork

Frame formwork or frame formwork is used to denote formwork systems for wall formwork and ceiling formwork made of steel or aluminum, more rarely made of plastic, in which the frame elements (frame including the formwork skin) are permanently welded at the factory and therefore consist of only a few individual components.

Fixed sizes of the formwork elements as well as system components for wall connections and connections enable large areas to be formed quickly. The formwork work is also accelerated by the ability to move larger formwork units by crane. In addition, this formwork solution has the advantage that it can also be used to create surfaces with exposed concrete.

Frame formwork for ceilings

Frame formwork are formwork systems in which the formwork elements consist of factory-welded aluminum, steel or plastic frames on which the formwork (plywood or plastic) is attached. Frame formwork for ceilings (ceiling formwork) consists of a horizontal supporting structure that supports the formlining and transfers the resulting forces into a supporting structure. A distinction is usually made between girder slab formwork, slab tables and modular slab formwork systems made from panels.

In the case of panel slab formwork, frames are supported on beams or directly on supports. In contrast to frame formwork for walls, the forces are not transmitted via form anchors, but rather to supports. Vertical loads are diverted into the building using slab props and the horizontal loads, e.g. via so-called Guyings.

Formwork

The formwork is a temporary technical construction that is assembled from various components and serves as a mold for the liquid fresh concrete. Formwork is required wherever fresh concrete is processed, regardless of whether it is produced in precast or in-situ concrete, e.g. in the area of components made of concrete, reinforced concrete, prestressed concrete and fiber concrete as well as when using lightweight concrete, normal concrete and heavy concrete.

The formwork gives the concrete its final shape, is responsible for the support and dimensional accuracy of the component and at the same time transfers the forces created by the weight of the concrete into the substructure. In addition, the formwork is jointly responsible for the structure and the later appearance of the concrete surface (e.g. rough, smooth, certain grain, etc.).

The formwork remains immovable until the concrete has reached its strength and load-bearing capacity. After the concrete has hardened, the formwork is usually removed.

Formwork anchor

Formwork anchors are connecting elements that connect two opposing formwork panels or formwork and counter-formwork. As long as the fresh concrete poured into the formwork is not yet solid, it exerts pressure on the formwork. For this reason, when shuttering a wall, the vertical formwork panels are connected to one another using shuttering anchors. They prevent the formwork and fresh concrete from drifting apart and indicate the shape and thickness of the component. The formwork anchors are located inside the concrete component.

Anchor systems for the formwork consist of threaded rods, threaded sleeves and nuts. The steel threaded rods take on the function of load transfer. On each side these protrude through holes in the formwork, where they are screwed tight on the outside with nuts. So that the steel rod can be removed again after stripping, it is inserted in a threaded sleeve that remains in the concrete component.

A metal or plastic cone connects the sleeve to the formwork at both ends so that the liquid concrete cannot leak out of the hole in the formwork. After removal, each form anchor leaves a hole in the finished component. The resulting holes are closed with locking plugs. These can be closed or plastered with weather-resistant PE plugs, aluminum or concrete plugs.

Formwork system

A formwork system consists of various components such as formwork panels or formwork panels, scaffolding, scaffolding, formwork beams, supports, formwork clamps, etc., which are used as required. Decisive for the selection of the formwork system and the individual components are the area of application and the complexity of the planned structure or component shapes.

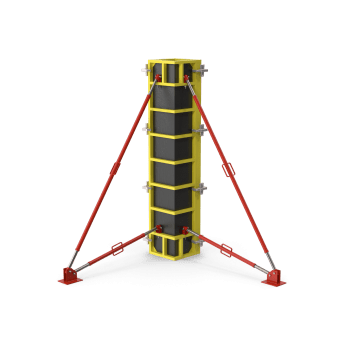

Depending on the purpose and area of application, a distinction is made between the following formwork systems:

- Bridge formwork

- Slab formwork

- Foundation formwork

- Manual shuttering

- Climbing systems

- Frame formwork

- Circular formwork

- Column formwork

- Diverse formwork

- Special formwork

- Large-area formwork

- Tunnel formwork

- Wall formwork

Protective scaffolding

A protective scaffolding is a temporary building structure that can be assembled from individual scaffolding components and then disassembled again. Protective scaffolding can serve both as safety scaffolding to protect people from falling, and in the form of protective roofs to protect people and other objects against falling material and objects.

Slab formwork with beams

Wall, column or slab formwork (so-called girder slab formwork) is referred to as girder formwork, in which the formwork is supported by formwork girders, while a bolt system made of steel profiles ensures quick connections of the elements. The beam formwork can be individually adapted to complex shapes and high loads. In the basic assembly system elements are assembled and used as appropriate formwork. The carriers remain unchanged and can be used again after dismantling.

Large-area formwork is suitable for all structural engineering tasks. They are used to produce large-format or self-supporting walls, ceilings or supports, e.g. in apartment, bridge, tunnel or power plant construction. For normal storey heights in residential construction, formwork props are predominantly used. For higher storey heights, the supports are horizontally connected to one another for stabilization or shoring is used. Often, concrete buildings with high demands on surfaces and anchor image can be performed efficiently with beam formwork.

Shoring

Shoring are a temporary support for parts of a structure, which transfer the forces that arise from its own weight into the substructure. They are used until the structure itself is sufficiently load-bearing for the dead loads as well as any associated traffic loads.

Beam shuttering

Different systems are available for beams, depending on the requirements. Beam formwork enables the ceiling and the beam to be concreted in one operation without additional anchors and costly wooden supports, which significantly reduces the workload.

In the case of beams, a distinction is made between field beams and edge beams. Beams can be made in advance or at the same time as the ceiling. Formwork solutions provided by the customer are used where system formwork cannot be used.

Field beams

Field beams are located inside the ceiling field. The slab formwork is connected on both sides of the beam. The joist formwork is matched to the slab formwork or vice versa. The wooden formwork beams can be arranged horizontally or vertically in the area of the beam clamps. Beam formwork can also be pre-assembled and used in units. In some cases, placing the joists on tables can be the more efficient solution.

Edge beams

Edge beams are arranged at the end of the ceiling. They divert the forces in walls or columns. On the outside and inside, opposite beam clamps are arranged, which transfer the load of the fresh concrete into the substructure. The substructure consists of longitudinal and transverse girders arranged over a supporting frame. The formwork for edge beams can also be designed as tables, which significantly reduces the workload.

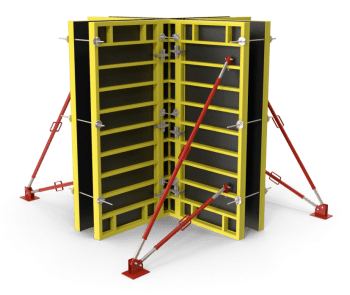

Wall formwork

Wall formwork or wall formwork is frame formwork for the wall. They consist of wooden panels on beams made of wood, metal or plastic elements, which form the supporting structure or the supporting structure. These modular systems are characterized by a wide range of possible uses and a long service life.

The wall formwork panels are usually set up against one another as a negative at the required wall thickness and braced with formwork anchors. This type of construction is called double-sided wall formwork. If the building structure on one side of the wall cannot be used for reasons of space, then the so-called single-sided wall formwork is used.

Depending on the construction, a distinction is made between girder wall formwork and frame formwork.

Scaffolding systems

Scaffolding systems are temporary structures to provide a safe workplace on construction sites and the necessary access. They are used for the construction, maintenance, repair and demolition of structures. According to the regulation in Germany, scaffolding systems must also fulfill a protective function.

Construction site

A construction site (also called a work site) is a temporary production site specifically specified by the client, on which a structure is built, converted or demolished with the help of workers, machines, equipment and building materials, or on which a building project is carried out. A distinction is made between fixed construction sites and mobile construction sites, as well as between permanent construction sites and temporary construction sites according to the duration.

In addition to the names of building areas, there is so-called Construction field. This includes areas on the building site or in its immediate vicinity, on which building materials are stored, equipment is set up or the construction site facilities are housed during the construction period. In addition, there are areas and measures for traffic safety or construction site bypassing and bypassing in the vicinity of the construction site.

Slab formwork

Ceilings are switched off at the edges in various designs. The type of edge formwork depends on the structure. Different systems are available for slab edge shuttering and beams, depending on the requirements. Beam formwork enables the ceiling and the beam to be concreted in one operation without additional anchors and costly wooden supports, which significantly reduces the workload.

Edge formwork for walls

In areas with walls, the slab formwork closes on the inside of the walls. Therefore it cannot be used for the edge formwork. In this case, the vertical edge formwork is attached to the outside of the walls. There are different system solutions for this type of formwork, whereby the tie points of the wall formwork are used. The distance between the anchors results from the wall formwork system used (e.g. large-area formwork or panel formwork).

Edge formwork with exposed slab end

With free ceiling ends, the ceiling formwork can be combined with the edge formwork. In the case of edge supports, the formwork is bridged horizontally on site.

Ceiling formwork system

Slab tables are formwork systems with slab props, mostly in standard formats of 10 to 15 m², by means of which large slab areas can be realized in a few repositioning processes. To assemble the ceiling props, the table top structures are lifted with the crane. The slab tables are moved to the next operational position by crane or a moving car, additionally required slab tables are connected and the mating areas are connected with the conventional large-area formwork.

Compared to girder and panel formwork, which is switched on and off in individual parts, the workload is reduced considerably with slab tables. A mandatory requirement for the use of slab tables is, however, that the structure has a minimum formwork area. It is therefore necessary to determine beforehand whether the structure will cross this boundary and whether sufficient lifting platforms, cranes etc. are available for this type of ceiling formwork.

Scaffolding

Scaffolding is temporary construction of various uses and variable heights, lengths and widths. They are assembled on the construction site from individual scaffolding components to form shoring, protective scaffolding, work platforms or site accesses and disassembled again after their use. Modern system scaffolding that is used in scaffolding consists of prefabricated metallic components. Due to the high technical and safety requirements, the manufacture of scaffolding and its safe assembling and disassembling are subject to strict legal regulations.

Scaffolding differ according to the type of use, the type of construction and the type of training:

Usage type

- Scaffolding system (reinforced scaffolding, special scaffolding structures)

- Shoring systems

- Protective scaffolding (working scaffolding with clothing, protective roof, roof safety scaffolding, safety scaffolding)

Design type

- Type of execution (tubular steel coupling, frame scaffolding, ladder scaffolding, modular system)

- Support system (standing scaffolding, hanging scaffolding, bracket scaffolding)

Type of assembly

- Facade scaffolding

- Allround scaffolding

- Mobile scaffolding

Climbing formwork

Climbing formwork systems consist of wall formwork systems (girder or frame formwork) and different climbing brackets that are firmly assembled to form a moving unit. The advantage of the climbing formwork is that it can be set directly into the next concreting section to save time.

Depending on whether or not a crane is required to move upwards, a distinction is made between crane-dependent and crane-independent climbing / moving formwork. The crane-independent climbing formwork is called self-climbing formwork. This is moved to the next concreting section by lifting devices on climbing rails.

In the case of crane-dependent climbing formwork, a distinction is made between guided and unguided climbing / moving formwork. With guided climbing formwork, the scaffolding on which the formwork is attached is pulled up on guide rails with the crane. This enables safe implementation even in windy conditions. In the case of unguided climbing formwork, this is separated from the structure and hung in the next concreting section using a crane.

Panel slab formwork with drop head

Panel slab formwork with drop head enables the elements and the side members to be stripped early, which reduces the amount required. Drop head systems consist of supports, drop heads, cover strips and panels. The heads are secured to the supports with quick-release fasteners. A mechanism on the drop head can be used to lower the carrier and frame elements. In this way, the material can be used for the next job after just one day.

Panel slab formwork without early stripping

The formwork system of the panel slab formwork without early stripping consists of a column, column head and formwork element. The support heads are attached to the support ceiling with screws. Then the formwork elements are hooked into the column head, swiveled up and supported at the respective crossing point. In the case of heights of up to 3.20 m, which are common in residential construction, shuttering is done from the ground. At greater heights, mobile scaffolds or lifting platforms are used.

Frame scaffolding

Frame scaffolding (also known as plug-in frame scaffolding) consists of only a few individual elements that are quickly and easily assembled on site and dismantled again after use. The components of this steel scaffolding system are the base spindle, assembly frame, scaffolding deck, toe board, railing and diagonal. Screws are not required. They are mainly used for facades as work scaffolding, protective scaffolding or standing scaffolding.

Frame formwork

Frame formwork or frame formwork is used to denote formwork systems for wall formwork and ceiling formwork made of steel or aluminum, more rarely made of plastic, in which the frame elements (frame including the formwork skin) are permanently welded at the factory and therefore consist of only a few individual components.

Fixed sizes of the formwork elements as well as system components for wall connections and connections enable large areas to be formed quickly. The formwork work is also accelerated by the ability to move larger formwork units by crane. In addition, this formwork solution has the advantage that it can also be used to create surfaces with exposed concrete.

Frame formwork for ceilings

Frame formwork are formwork systems in which the formwork elements consist of factory-welded aluminum, steel or plastic frames on which the formwork (plywood or plastic) is attached. Frame formwork for ceilings (ceiling formwork) consists of a horizontal supporting structure that supports the formlining and transfers the resulting forces into a supporting structure. A distinction is usually made between girder slab formwork, slab tables and modular slab formwork systems made from panels.

In the case of panel slab formwork, frames are supported on beams or directly on supports. In contrast to frame formwork for walls, the forces are not transmitted via form anchors, but rather to supports. Vertical loads are diverted into the building using slab props and the horizontal loads, e.g. via so-called Guyings.

Formwork

The formwork is a temporary technical construction that is assembled from various components and serves as a mold for the liquid fresh concrete. Formwork is required wherever fresh concrete is processed, regardless of whether it is produced in precast or in-situ concrete, e.g. in the area of components made of concrete, reinforced concrete, prestressed concrete and fiber concrete as well as when using lightweight concrete, normal concrete and heavy concrete.

The formwork gives the concrete its final shape, is responsible for the support and dimensional accuracy of the component and at the same time transfers the forces created by the weight of the concrete into the substructure. In addition, the formwork is jointly responsible for the structure and the later appearance of the concrete surface (e.g. rough, smooth, certain grain, etc.).

The formwork remains immovable until the concrete has reached its strength and load-bearing capacity. After the concrete has hardened, the formwork is usually removed.

Formwork anchor

Formwork anchors are connecting elements that connect two opposing formwork panels or formwork and counter-formwork. As long as the fresh concrete poured into the formwork is not yet solid, it exerts pressure on the formwork. For this reason, when shuttering a wall, the vertical formwork panels are connected to one another using shuttering anchors. They prevent the formwork and fresh concrete from drifting apart and indicate the shape and thickness of the component. The formwork anchors are located inside the concrete component.

Anchor systems for the formwork consist of threaded rods, threaded sleeves and nuts. The steel threaded rods take on the function of load transfer. On each side these protrude through holes in the formwork, where they are screwed tight on the outside with nuts. So that the steel rod can be removed again after stripping, it is inserted in a threaded sleeve that remains in the concrete component.

A metal or plastic cone connects the sleeve to the formwork at both ends so that the liquid concrete cannot leak out of the hole in the formwork. After removal, each form anchor leaves a hole in the finished component. The resulting holes are closed with locking plugs. These can be closed or plastered with weather-resistant PE plugs, aluminum or concrete plugs.

Formwork system

A formwork system consists of various components such as formwork panels or formwork panels, scaffolding, scaffolding, formwork beams, supports, formwork clamps, etc., which are used as required. Decisive for the selection of the formwork system and the individual components are the area of application and the complexity of the planned structure or component shapes.

Depending on the purpose and area of application, a distinction is made between the following formwork systems:

- Bridge formwork

- Slab formwork

- Foundation formwork

- Manual shuttering

- Climbing systems

- Frame formwork

- Circular formwork

- Column formwork

- Diverse formwork

- Special formwork

- Large-area formwork

- Tunnel formwork

- Wall formwork

Protective scaffolding

A protective scaffolding is a temporary building structure that can be assembled from individual scaffolding components and then disassembled again. Protective scaffolding can serve both as safety scaffolding to protect people from falling, and in the form of protective roofs to protect people and other objects against falling material and objects.

Slab formwork with beams

Wall, column or slab formwork (so-called girder slab formwork) is referred to as girder formwork, in which the formwork is supported by formwork girders, while a bolt system made of steel profiles ensures quick connections of the elements. The beam formwork can be individually adapted to complex shapes and high loads. In the basic assembly system elements are assembled and used as appropriate formwork. The carriers remain unchanged and can be used again after dismantling.

Large-area formwork is suitable for all structural engineering tasks. They are used to produce large-format or self-supporting walls, ceilings or supports, e.g. in apartment, bridge, tunnel or power plant construction. For normal storey heights in residential construction, formwork props are predominantly used. For higher storey heights, the supports are horizontally connected to one another for stabilization or shoring is used. Often, concrete buildings with high demands on surfaces and anchor image can be performed efficiently with beam formwork.

Shoring

Shoring are a temporary support for parts of a structure, which transfer the forces that arise from its own weight into the substructure. They are used until the structure itself is sufficiently load-bearing for the dead loads as well as any associated traffic loads.

Beam shuttering

Different systems are available for beams, depending on the requirements. Beam formwork enables the ceiling and the beam to be concreted in one operation without additional anchors and costly wooden supports, which significantly reduces the workload.

In the case of beams, a distinction is made between field beams and edge beams. Beams can be made in advance or at the same time as the ceiling. Formwork solutions provided by the customer are used where system formwork cannot be used.

Field beams

Field beams are located inside the ceiling field. The slab formwork is connected on both sides of the beam. The joist formwork is matched to the slab formwork or vice versa. The wooden formwork beams can be arranged horizontally or vertically in the area of the beam clamps. Beam formwork can also be pre-assembled and used in units. In some cases, placing the joists on tables can be the more efficient solution.

Edge beams

Edge beams are arranged at the end of the ceiling. They divert the forces in walls or columns. On the outside and inside, opposite beam clamps are arranged, which transfer the load of the fresh concrete into the substructure. The substructure consists of longitudinal and transverse girders arranged over a supporting frame. The formwork for edge beams can also be designed as tables, which significantly reduces the workload.

Wall formwork

Wall formwork or wall formwork is frame formwork for the wall. They consist of wooden panels on beams made of wood, metal or plastic elements, which form the supporting structure or the supporting structure. These modular systems are characterized by a wide range of possible uses and a long service life.

The wall formwork panels are usually set up against one another as a negative at the required wall thickness and braced with formwork anchors. This type of construction is called double-sided wall formwork. If the building structure on one side of the wall cannot be used for reasons of space, then the so-called single-sided wall formwork is used.

Depending on the construction, a distinction is made between girder wall formwork and frame formwork.